Gotthard Base Tunnel

Project description

The Gotthard Route is part of the international north-south alpine transversal. It marks one of the most important high-profile projects Amberg has been involved in recent years.

With a total length of 57 kilometers, the tunnel is one of the world’s longest railway tunnels. The enormous overlying rockmass of up to 2300 meters drives the rock temperature up to 50 degrees Celsius. The geology proved itself as a very challenging factor for the construction as well. Penninic Gneiss, the Gotthard Granite massif, the Piora sedimentary syncline were excavated with tunnel boring machines, the approx. 1.2 km long sedimentary rock section of the Tavetsch Massif was driven in a specifically developed conventional method.

Amberg was responsible for the design of the project and the construction supervision in an engineering joint-venture. Furthermore, safety and ventilation design was carried out by Amberg.

Project details

Shafts I and II Sedrun

Amberg was responsible for the logistic concept through the shafts at Sedrun. Amberg designed the shafts, the shaft heads shafts and the hoist. Furthermore, Amberg Engineering also was responsible for the side supervision of the intermediate access point in Sedrun.

Two shafts were sunk as part of the the intermediate access at Sedrun. Shaft I was constructed conventionally with the shaft sinking-method from top to bottom. The design of shaft I was based on the logistic necessities of the supply. The result was a shaft with the geometric dimensions of 800m depth and 8.60m inner diameter. A large-cage system with counterweight was installed for the transport. Shaft I supplied the entire section with electricity and material. Also the muck of the drives was hoisted out through shaft I.

Shaft II is located close to shaft I. Due to the fact that the foot of shaft II was accessible, a pilot boring was drilled top – down which was afterwards widened with a raise-drill. The final diameter of 7m was reached with a shaft boring machine. Shaft II was used to transport large machinery and ventilation.

Multifunction Station Faido

Amberg was in charge of the challenging design planning and construction management of MFS Faido.

There are two multifunction stations (MFS) in the Gotthard Base Tunnel: one at Sedrun and one at Faido. The MFS were constructed at the end of the respective intermediate access. The intermediate access allowed to reduce the overall construction time because they created additional heading faces . Also, the geological risk zones could be excavated faster.

The MFS have many purposes. They are the cross over points from one tunnel to the other, the security stops for trains in emergency and they contain all the installations which are needed to operate the tunnel . These installations are mainly electricity, communication, signaling, ventilation, water.

The construction of the MFS Faido was challenging because of the unexpected geological conditions which resulted in large plastic deformations, rockburst and rockfalls.

Re-utilization of the excavated material

Right from the start of the project of Gotthard Base-Tunnel the re-utilization of the muck as raw material for aggregate was stipulated as a policy: as much as possible of the excavated material (28.7. mio tons in total) were reused, either directly on site or for other purposes like landfills etc.

A portion of the material was recycled for the tunnel itself as concrete. High requirements were stipulated for the quality of the concrete mix designs: . The concrete must withstand high temperature, aggressive ground-waters and must be long lasting. Extensive evaluation tests in a 1:1 scale were carried out to evaluate the right concrete mix design . All the tests were design, run and assessed in the Hagerbach Test Gallery (VSH) and were also supervised by the staff of VSH.

The rest of the material was dumped for landscape design, renaturalisation and landfills.

Optimization of the lining

After the rock support works Amberg scanned the tunnel vault with the TMS Tunnelscan Software. Based on these data it was possible to calculate the optimal formwork configuration and the exact position of the formwork in the tunnel. Thanks to this optimization thousands of cubic meters of concrete could be saved which reduced the cost immensely

Geological risk zones

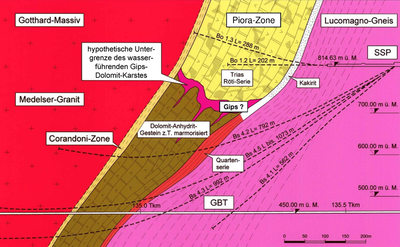

Amberg developed the concept for the exploration of the two most important geological risk zones and managed the task force for the exploration of the Piora zone.

Amberg also carried out the geotechnical monitored in the explorationareas . The data were put online and therefore always available. This lead to a good overview of all security and construction data. The most important geological risk zones in the Gotthard massif were well known from earlier underground projects. The most important and difficult zones were the Tavetsch intermediate massif and the Piora zone. The Tavetsch intermediate massif is close to Sedrun and the Piora zone close to Faido. The two zones were massively explored in an early state of the project to get to know better the size of the risk zones. The Tavetsch intermediate massif was explored with directed drillings with lengths of about 2km from the surface down to the level of the base tunnel.

In the Piora zone, a 5km long exploratory tunnel was constructed 300m above the later base tunnel level from which exploratory borings were drilled were down to verify the geological conditions on the level of the future Base-Tunnel.

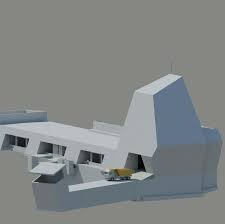

The portal building Faido

Amberg was responsible for the design and construction management of the portal building in Faido.

The portal building Faido houses ventilation installations, technical rooms for the rail technology, building services rooms and the Faido substation of the Swiss Federal Railways (SBB).