References

- Amberg Engineering

- Amberg Technologies

- Road

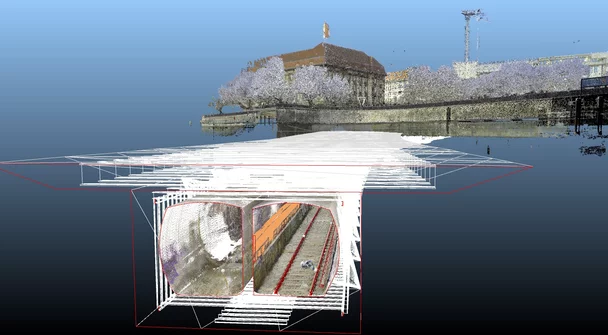

Zurich, Switzerland

Uetliberg Tunnel

- Amberg Engineering

- Amberg Technologies

- Geophysics

- Rail

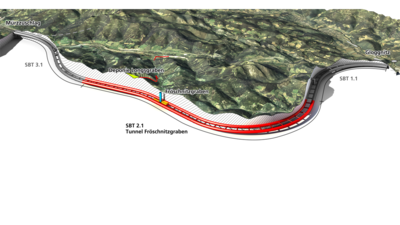

Innsbruck, Austria

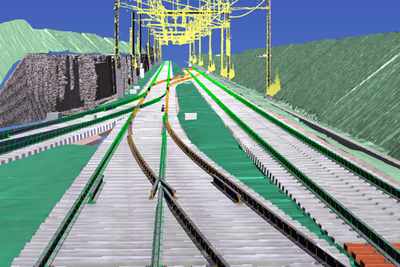

Brenner Base Tunnel

- Amberg Engineering

- Rail

Albula, Switzerland

Albula Tunnel II

- Amberg Engineering

- Rail

Brunnen–Fluelen, Switzerland

Axen Tunnels

- Amberg Engineering

- Road

Rio de Janeiro, Brazil

Porto Maravilha

- Amberg Engineering

- Rail

Klosters, Switzerland

Vereina Railtunnel

- Amberg Technologies

- Geophysics

Karak, Malaysia

Pahang Selangor Raw Water Transfer Project

- Amberg Technologies

- Rail

Beijing - Tianjin, China

Olympic High Speed Line Beijing - Tianjin

- Amberg Technologies

- Geophysics

Gansu, China

Wushaoling Rail Tunnel

- Amberg Technologies

- Geophysics

Stavanger, Norway

Hundvag Tunnel

- Amberg Engineering

- Amberg Technologies

- Geophysics

- Underground

Uva Province, Sri Lanka

Uma Oya Project

- Amberg Technologies

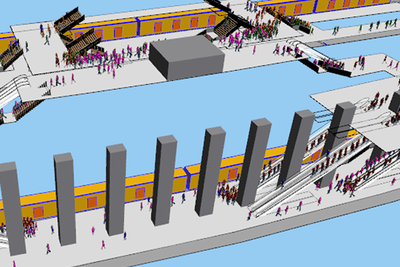

- Metro

Toronto, Canada

Subway Toronto

- Amberg Technologies

- Geophysics

San Jose, Costa Rica

Cachí Hydropower Plant

- Amberg Technologies

- Geophysics

- Utility

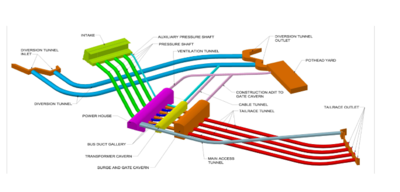

Pulga, India

Parbati Hydropower Project

- Amberg Technologies

- Geophysics

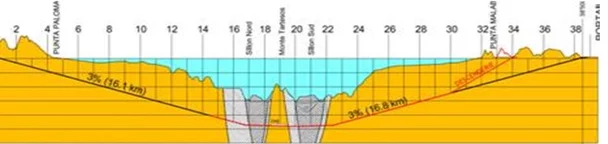

Limón Dam, Peru

Olmos Irrigation

- Amberg Technologies

- Tunnel

New York, United States

East side access New York

- Amberg Technologies

- Metro

- Tunnel

Ningbo, China

Ningbo Metro

- Amberg Technologies

- Geophysics

Stavanger, Norway

Ryfast

- Amberg Technologies

- Tunnel

Oslo, Norway

Follo Line

- Amberg Technologies

- Tunnel

Eurajoki, Finland

Onkalo spent nuclear fuel repository

- Amberg Technologies

- Rail

Xi’an – Chengdu, China

Xi’an – Chengdu

- Amberg Technologies

- Rail

Beijing–Shanghai, China

Beijing – Shanghai

- Amberg Technologies

- Rail

Mecca–Medina, Saudi Arabia

Mekka - Medina

- Amberg Technologies

- Rail

Amsterdam, Netherlands

GVB Amsterdam

- Amberg Technologies

- Rail

Chur, Switzerland

Rhätische Bahn

- Amberg Technologies

- Rail

Nürnberg-Ingolstadt, Germany

Deutsche Bahn

- Amberg Technologies

- Rail

- Tunnel

London, United Kingdom

Crossrail London

- Amberg Technologies

- Geophysics

- Tunnel

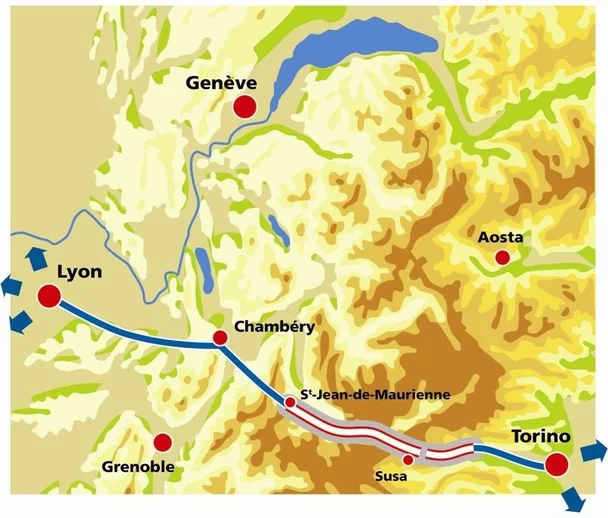

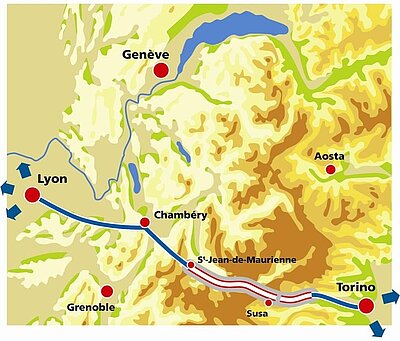

Saint Jean de Maurienne, France / Susa, Italy

Lyon-Turin Exploratory Tunnel La Maddalena

- Amberg Engineering

- Amberg Technologies

- VersuchsStollen Hagerbach

- Geophysics

- Rail

- Tunnel

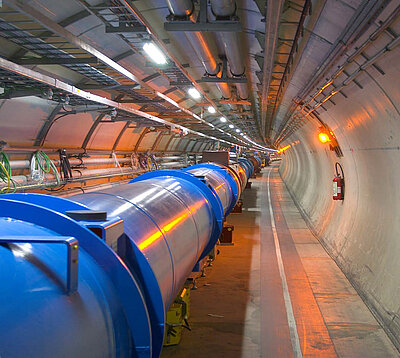

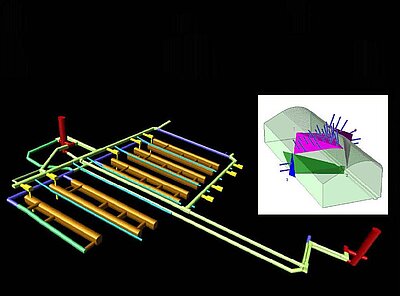

Gotthard, Switzerland

Gotthard Base Tunnel

- Amberg Engineering

- Amberg Technologies

- VersuchsStollen Hagerbach

- Rail

- Tunnel

Sigirino, Switzerland

Ceneri Base Tunnel

- Amberg Technologies

- Rail

London, United Kingdom

Network Rail

- Amberg Engineering

- Road

St. Gallen, Switzerland

Cover Rosenberg - OLMA

- Amberg Engineering

- Rail

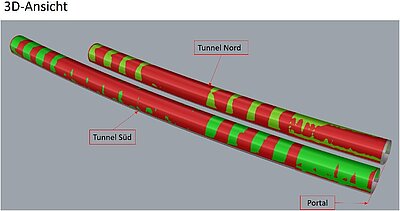

Bözberg, Switzerland

Bözberg Tunnel

- Amberg Engineering

- Metro

Porto, Portugal

Metro Porto

- Amberg Engineering

- Underground

Geneva, Switzerland

CERN - new particle accelerators

- Amberg Engineering

- Underground

Sargans, Switzerland

Chip Factory Underground

- Amberg Engineering

- Underground

Mont Terri, Switzerland

Full-Scale Emplacement Experiment Lucoex

- Amberg Engineering

- BIM

- Rail

Montreal, Canada

Montreal International Airport

- Amberg Technologies

- Rail

Australia

Canberra light rail stage 1

- Amberg Technologies

- Rail

China

Hankou-Danjiangkou wartung und upgrade

- Amberg Engineering

- Road

Brasil

Rodovia dos Tamoios

- Amberg Engineering

- Rail

Cernadilla, Spain

High-Speed Train Madrid - Galicia

- Amberg Engineering

- Amberg Infra 7D

- BIM

- Rail

Rastatt, Germany

Rastatt Tunnel

- Amberg Engineering

- Road

Simplon pass, Switzerland

Meggeri-Kapf-Schallbett

- Amberg Engineering

- Underground

Switzerland

Schollberg quarry

- Amberg Engineering

- Underground

Singapore

Underground Science City

- Amberg Engineering

- Underground

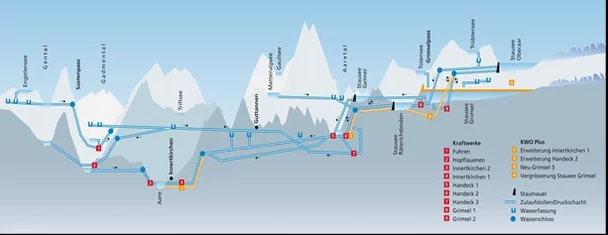

Grimsel, Switzerland

Gas permeable seal test (GAST)

- Amberg Engineering

- Metro

Bucharest, Romania

Metro Bucharest

- Amberg Technologies

- Rail

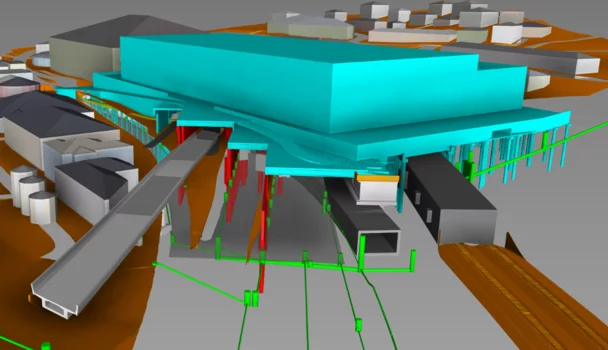

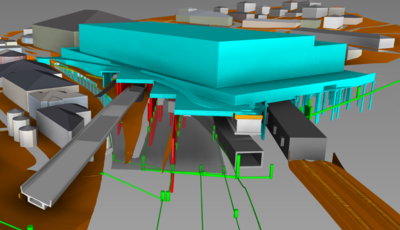

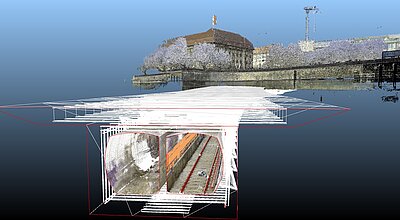

Zurich, Switzerland

BIM at Zurich Airport

- Amberg Engineering

- Road

Zurich, Switzerland

Northern Bypass Zurich

- Amberg Engineering

- Amberg Technologies

- Underground

Flums, Switzerland

Hagerbach Test Gallery

- Amberg Engineering

- BIM

- Rail

Mellingen, Switzerland

Mellingen track replacement

- Amberg Engineering

- Metro

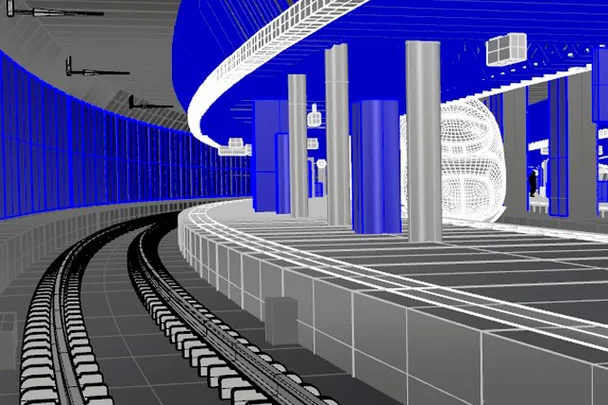

Stockholm, Sweden

BIM at Metro Stockholm

- Amberg Engineering

- Road

Leonberg, Germany

Engelberg Base Tunnel

- Amberg Engineering

- Rail

Katra, India

Katra Dharam Safety + Ventilation

- Amberg Engineering

- Underground

- Utility

Singapore

Utility Plants in rock caverns

- Amberg Engineering

- Underground

China

Sha Tin Sewage Treatment Works (HK) - QRA

- Amberg Technologies

- Tunnel

Germany

Brandberg tunnel

- Amberg Engineering

- Road

Slovakia

Soroška Tunnel

- Amberg Engineering

- Rail

Norway

Follobanen

- Amberg Engineering

- Road

India

Autram Ghat Tunnel

- Amberg Engineering

- Rail

Malaysia

Marang Tunnel

- Amberg Engineering

- Amberg Infra 7D

- Metro

Germany

U5 Metro Berlin

- Amberg Technologies

- Tunnel

China

ZhangJiHuai High Speed Railway

- Amberg Engineering

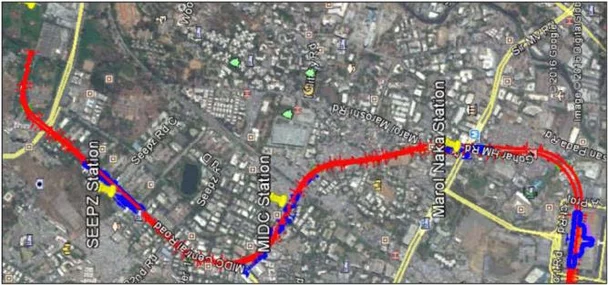

- Metro

India

Ahmedabad Metro

- Amberg Engineering

- Metro

Iran

Ahwaz Metro

- Amberg Engineering

- Underground

Chile

Alto Maipo

- Amberg Engineering

- Metro

India

Delhi Metro

- Amberg Engineering

- Road

Zurich, Switzerland

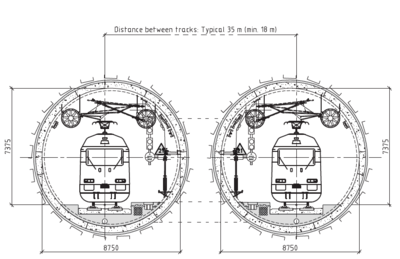

Gubrist tunnel - New construction of the 3rd tube

- Amberg Engineering

- Underground

Singapore

Jurong Rock Cavern

- Amberg Engineering

- Underground

Switzerland

Pumped Storage Plant, Lago Bianco

- Amberg Engineering

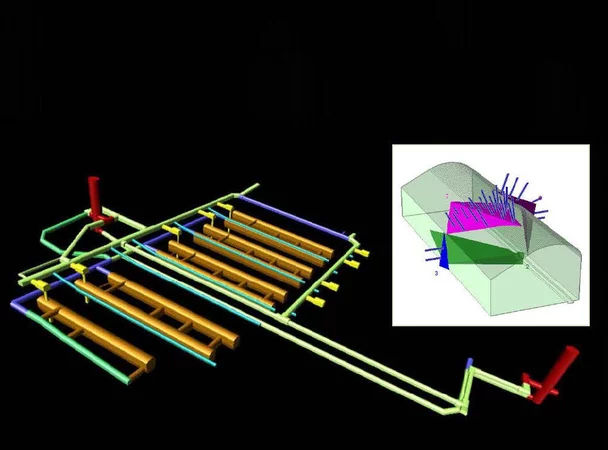

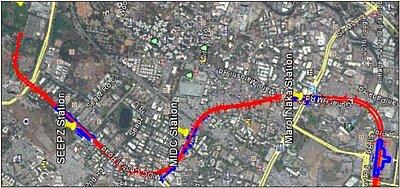

- Metro

India

Mumbai Metro Line 3

- Amberg Engineering

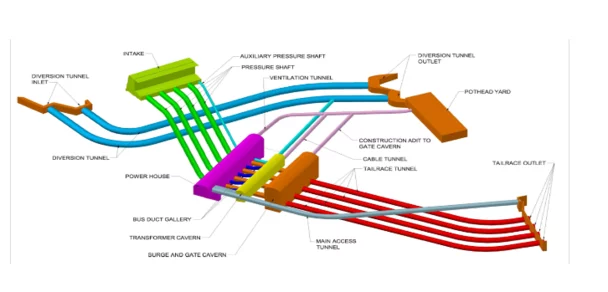

- Underground

India

Ratle Hydropower Project

- Amberg Engineering

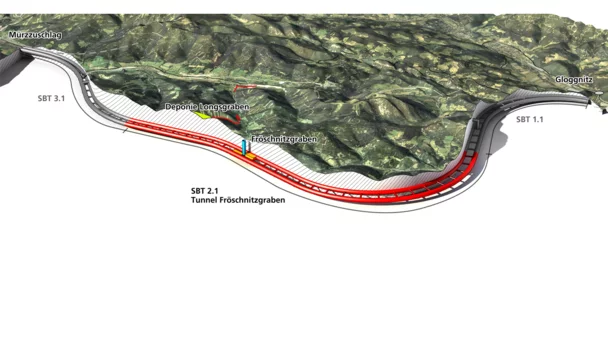

- Rail

Austria

Semmering Base Tunnel

- Amberg Engineering

- Road

United Arab Emirates

Suez Channel Tunnel

- Amberg Engineering

- Road

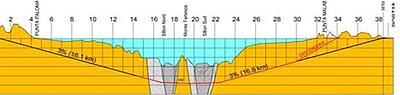

Switzerland

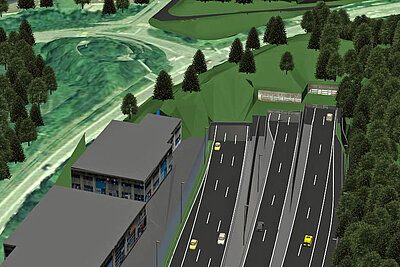

Zurich bypass - Uetliberg Tunnel

- Amberg Engineering

- Road

Mazandaran Province, Teheran-Shomal Freeway, Iran

Alborz Service Tunnel

- Amberg Engineering

- Rail

Katzelsdorf, Austria

Wienerwald Tunnel

- Amberg Engineering

- Road

Villa Carcina, Italy

A4 Motorway Connection Tunnel Villa Carcina

- Amberg Engineering

- Rail

Gothenburg, Sweden

Borasbanan

- Amberg Engineering

- Metro

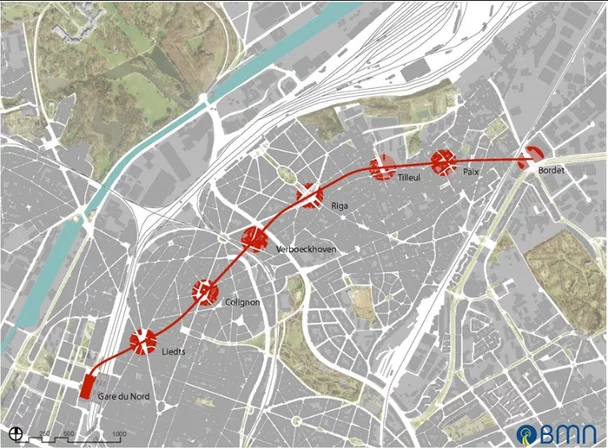

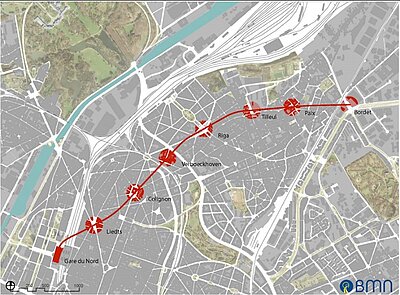

Brussels, Belgium

Brussels Metro North

- Amberg Engineering

- BIM

- Road

Lucerne, Switzerland

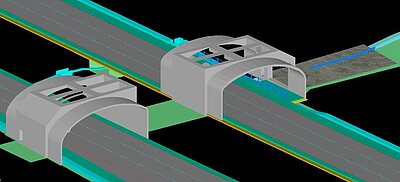

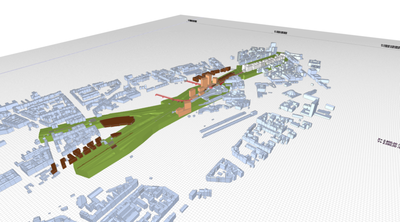

Overall system Lucerne Bypass

- Amberg Engineering

- Underground

Rancagua, Chile

El Teniente - New access tunnel

- Amberg Engineering

- BIM

- Rail

Frankfurt, Germany

Cornberg Tunnel renewal

- Amberg Engineering

- BIM

- Rail

Wilnsdorf, Germany

Rudersdorf Tunnel renewal

- Amberg Engineering

- Rail

Helsinki, Finland

FinEst Link

- Amberg Engineering

- Road

Stockholm, Sweden

Förbifart - Stockholm bypass

- Amberg Engineering

- Rail

Lyon, France

Lyon-Turin base tunnel

- Amberg Engineering

- Rail

- Road

Andermatt, Switzerland

Furka Tunnel

- Amberg Engineering

- Underground

Grimsel, Switzerland

Grimsel 3 pumped storage power plant

- Amberg Engineering

- Metro

Kolkata, India

Kolkata Metro Tunnel

- Amberg Engineering

- Rail

Gibraltar, Spain

Gibraltar Tunnel

- Amberg Engineering

- Road

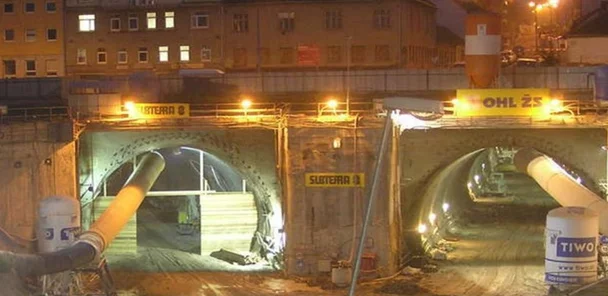

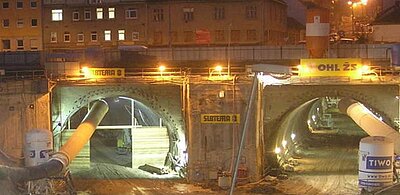

Brno, Czech Republic

Kralovopolsky Tunnel

- Amberg Engineering

- Metro

Paris, France

Metro Grand Paris Express, Line 17 north

- Amberg Engineering

- Metro

Lausanne, Switzerland

Métro m2 - Tunnel de Viret

- Amberg Engineering

- Road

Luzern, Switzerland

N2 - Lucerne city ring road

- Amberg Engineering

- Utility

Niagara Falls, Ontario, Canada

Niagara Tunnel

- Amberg Engineering

- Underground

- Utility

Kishtwar, India

Pakal Dul Hydro-Electric Power Plant

- Amberg Engineering

- Rail

Hamburg, Germany

Elb tunnel restoration

- Amberg Engineering

- Rail

- Road

Sochi, Russia

Sochi Tunnel 3

- Amberg Engineering

- Metro

Sao Paulo, Brazil

Sao Paulo Metro, Line 5 / purple

- Amberg Engineering

- BIM

- Rail

Berlin, Germany

Waisentunnel renovation

- Amberg Engineering

- Road

San Bernardino, Switzerland

San Bernardino Tunnel renewal

- Amberg Engineering

- BIM

- Rail

Berlin, Germany

S21-Berlin

- Amberg Engineering

- Metro

Barcelona, Spain

Sabadell Metro Extension

- Amberg Engineering

- Road

Madrid, Spain

Prosperity Motorway

- Amberg Engineering

- Rail

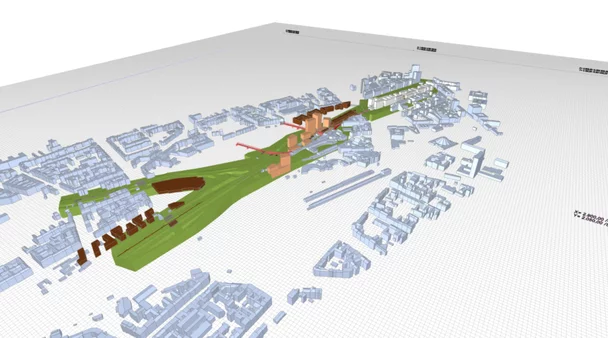

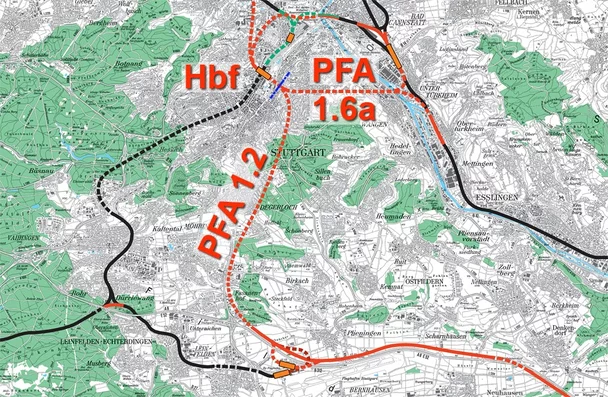

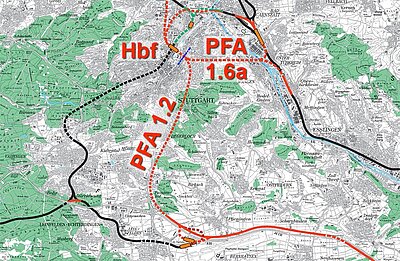

Stuttgart, Germany

Stuttgart 21

- Amberg Engineering

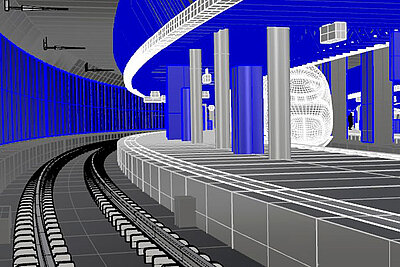

- Metro

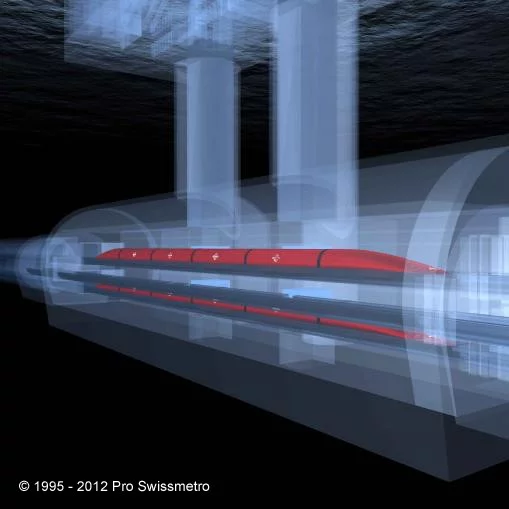

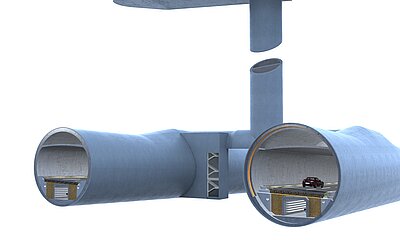

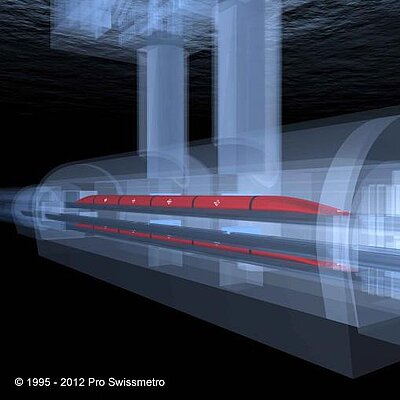

Zurich, Switzerland

Swissmetro

- Amberg Engineering

- Rail

Luzern, Switzerland

Lucerne deep railway station

- Amberg Engineering

- Rail

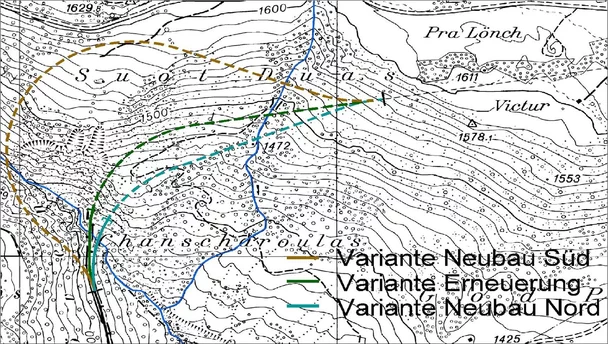

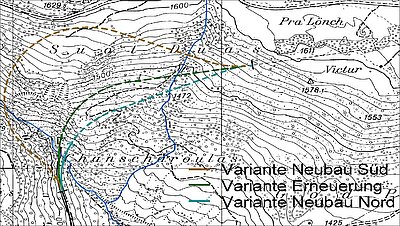

Ardez, Switzerland

Tasna Tunnel portal area Ardez

- Amberg Engineering

- Road

Brig, Switzerland

Riedberg Tunnel, A9

- Amberg Engineering

- Metro

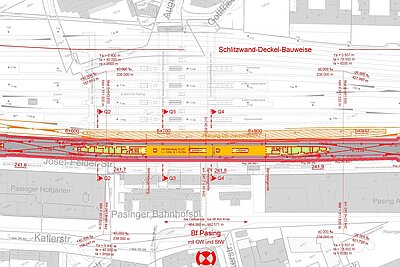

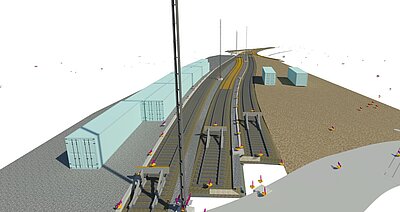

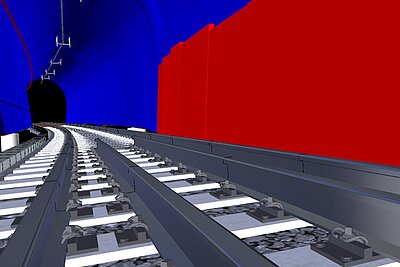

Munich, Germany

U5 Munich

- Amberg Engineering

- Road

Lima, Peru

Via Parque Rimac, Lima

- Amberg Engineering

- Tunnel

Schenefeld, Germany

European X-Ray Laser Facility, XFEL

- Amberg Engineering

- Rail

Basel II, carriageway renewal

- Amberg Engineering

- Road

Hägendorf, Switzerland

Belchen tunnel safety

- Amberg Engineering

- Rail

Morschach, Switzerland

BIM@RetroBIM Tunnel Oelberg

- Amberg Technologies

- Tunnel

China

Jingwen expressway

- Amberg Technologies

- Tunnel

Norway

The Bjonnas tunnel

- Amberg Technologies

- Tunnel

Sweden

Förbifart Stockholm (E4)

- Amberg Technologies

- Tunnel

Colombia

Toyo

- Amberg Technologies

- Rail

Cancún - Palenque, Mexico

Tren Maya

- Amberg Technologies

- Rail

North West England

Comprehensive Rail Survey for Track Renewal

- Amberg Technologies

- Rail

Asturias - Cantabrian Mountains, Spain

Pajares Tunnel

- Amberg Technologies

- Rail

Kanazawa - Tsuruga, Japan

Hokuriku Shinkansen Extension

- Amberg Engineering

- Metro

Paris, France