Generally speaking, several different transversal tunnel schemes – the layout of the tunnel’s cross section – are possible. The final decision for the best-suited tunnel system in each project has to be taken with respect to the specific requirements and boundary conditions.

Safety goals define the level of safety to be reached and they also define the residual risks to be accepted by the tunnel operator. The minimum is defined by relevant regulations like the TSI (Technical Specifications for Interoperability) and national normative documents. The “state of the art” of safety solutions for long rail tunnels, like the Gotthard or the Brenner Base Tunnel have as well a strong influence on the safety level. Safety goals are defined for the protection of passengers and staff, freight and the infrastructure respectively its availability.

The transversal tunnel scheme – output of an evaluation process including technical, geological, operational as well as safety aspects

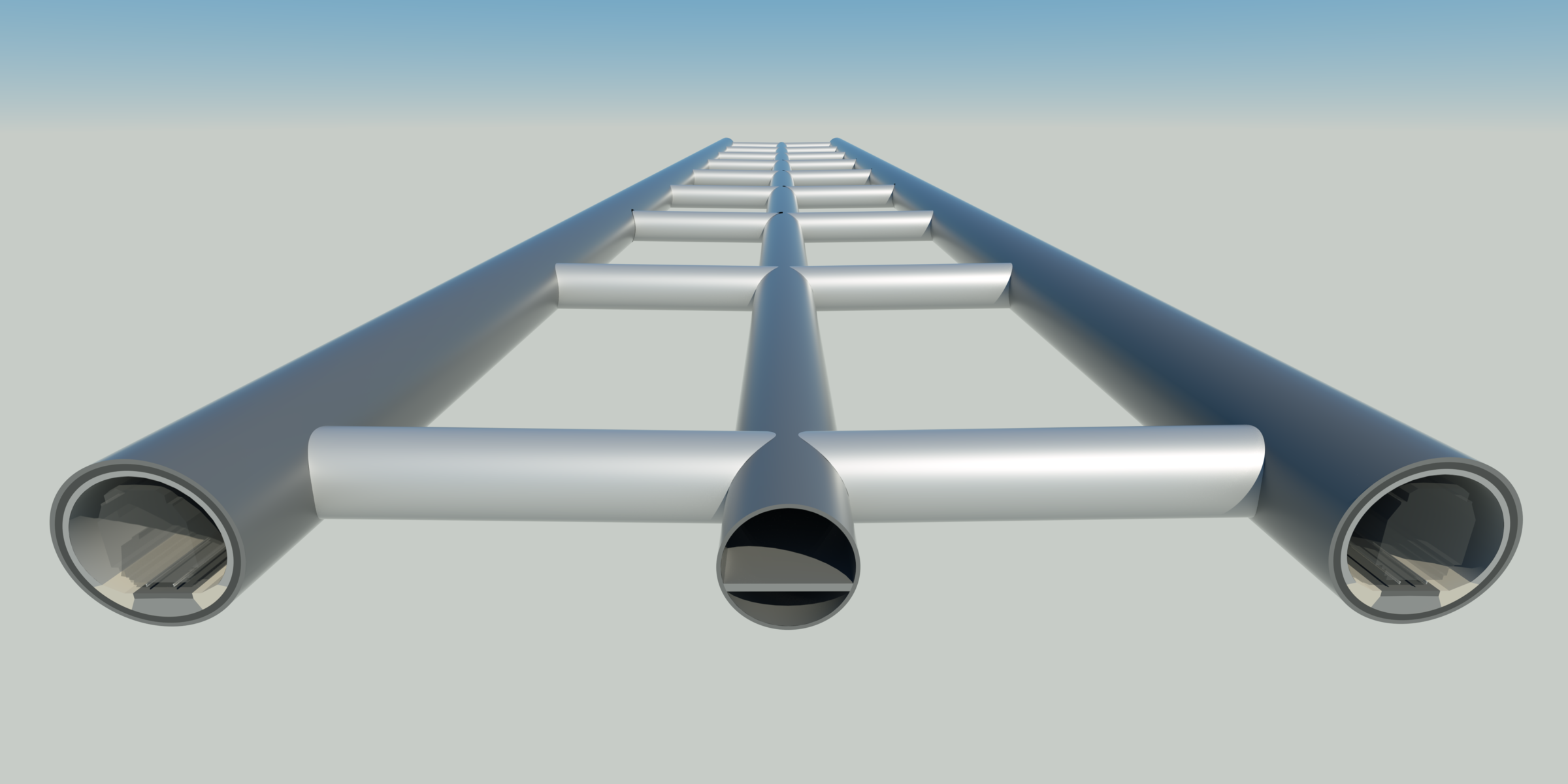

For FinEst Link, the following six transversal tunnel schemes were evaluated in a generic way in order to define the best-suited tunnel system: A) One double-track tunnel with dividing wall, B) One double-track tunnel and one service tunnel with cross passages, C) Two single-track tunnels with cross passages, D) Two single-track tunnels and one service tunnel with cross passages, E) Three single-track tunnels with cross passages, F) Immersed tunnel with separate cross sections and cross passages.

For the evaluation process a matrix was developed to assess the different tunnel options by us-ing seven criteria categories like tunnel construction, maintenance and operation or tunnel safety management with several subordinate criteria each.

For decision-making in the assessment of the tunnel schemes, a utility value analysis (a variants analysis based on a “scoring model”) was used. A scale of grades, ranging from 1 (worst solu-tion) to 5 (best solution) was selected for the evaluation of the individual criteria. The total score determined for each tunnel scheme was composed of the correspondingly weighted section scores.

As the result of the feasibility study and the performed evaluation it was concluded, that transver-sal tunnel scheme D consisting of two single-track tunnels and one service tunnel with cross pas-sages is the most suitable and best-possible tunnel layout for FinEst Link.

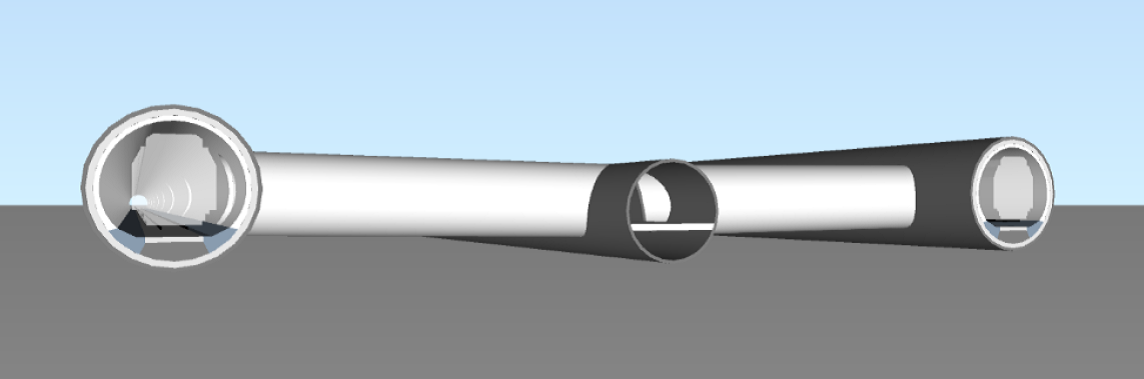

Picture: Layout of rescue stations: 450 meters long and cross-passages every 50 meters. Source: www.amberggroup.com

FinEst tunnel safety management – 4 rescue stations at a maximum interval of 20 km, each 450 m long with cross-passages every 50 m

The tunnel safety concept consists of prevention, mitigation, escape (self-rescue) and rescue. Generally, the most effective way to reduce the risks is prevention. Preventive measures reduce the occurrence of incidents. Mitigation, evacuation and rescue reduce the consequences of incidents and are less effective.

For the FinEst Link, the "trains help trains" principle is applied, meaning that interventions are done by train and passenger evacuation in case of an emergency is carried out by train. Infrastructural measures and operational or organizational measures are both important to achieve the safety goals. The most relevant infrastructural measures are cross passages at intervals of approximately 330 m connecting the two tunnel tubes with the service tunnel as well as four rescue stations for passenger trains along the subsea section of the tunnel with a length of 450 m long and cross passages every 50 m.

Two of the four rescue stations are located at the two intermediate access points and allow for the construction of an exhaust stack. These two rescue stations will be equipped with a smoke-extraction system to maintain tenable self-rescue conditions and limit smoke propagation.

The other two rescue stations are located in a subsea area where no connection to the surface can be created. Instead of a smoke-extraction system, these two rescue stations are equipped with fixed firefighting systems (FFFS) similar to solutions which have been applied in the Channel tunnel. A FFFS system limits fire development, heat release rate, smoke production and fire propagation along the incident train.

Ventilation and safety of long and deep tunnels – state of the art and new perspectives

Long rail tunnels require in most cases powerful mechanical ventilations. Besides requirements related to normal operation and maintenance, operational safety always requires a high level of smoke management. Identifying the optimum ventilation concept is essential for achieving proper performance and safety while keeping investment and operational cost at a reasonable level.

A significant number of very long tunnels have been commissioned, are under commissioning or under construction. Safety issues are crucial and have a large impact on design. The intervention philosophy and the safety elements must be integrated in the earliest design stages as they are mostly driving the design choices. A wise design can combine most of the required space for safety and technical installations with the space for installations during the construction phase. To do so, the key space consuming elements of the safety concept (escape route, rescue access and ventilation) must be defined in the first project stage to allow a perfect correlation with the construction requirements.

Read more about the European experience in risk management of long and deep tunnels presented by Dr. Marco Bettelini, Ventilation and Safety Specialist and Member of the Management Board Amberg Engineering, at the WTC 2016.

European experience in risk management of long and deep tunnelsVisionary underground solutions – Amberg is shaping the future

Amberg meets the challenges of the future. With the use of big data and cloud-based applications, new processes and working methods such as BIM are being developed and the company is geared up for the future. The exciting, international working environment offers excellent development opportunities and future perspectives.

Visit our website regularly to learn more about the challenging projects Amberg is involved and follow us on our social media channels.