In April, we took part in the amazing World Tunnel Congress 2024 in Shenzhen, China. The Chinese tunnelling and maintenance world demonstrated in an impressive way what is possible in modern tunnelling today. We have contributed with 2 papers and presentations:

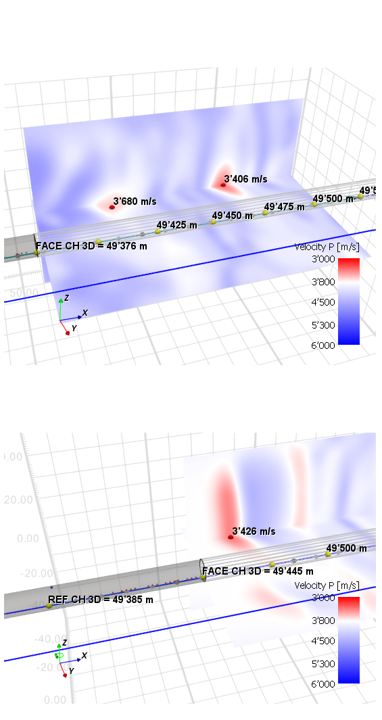

- Thomas Dickmann presented what is possible today in the field of continuous forecasting in mechanised tunnelling through rock.

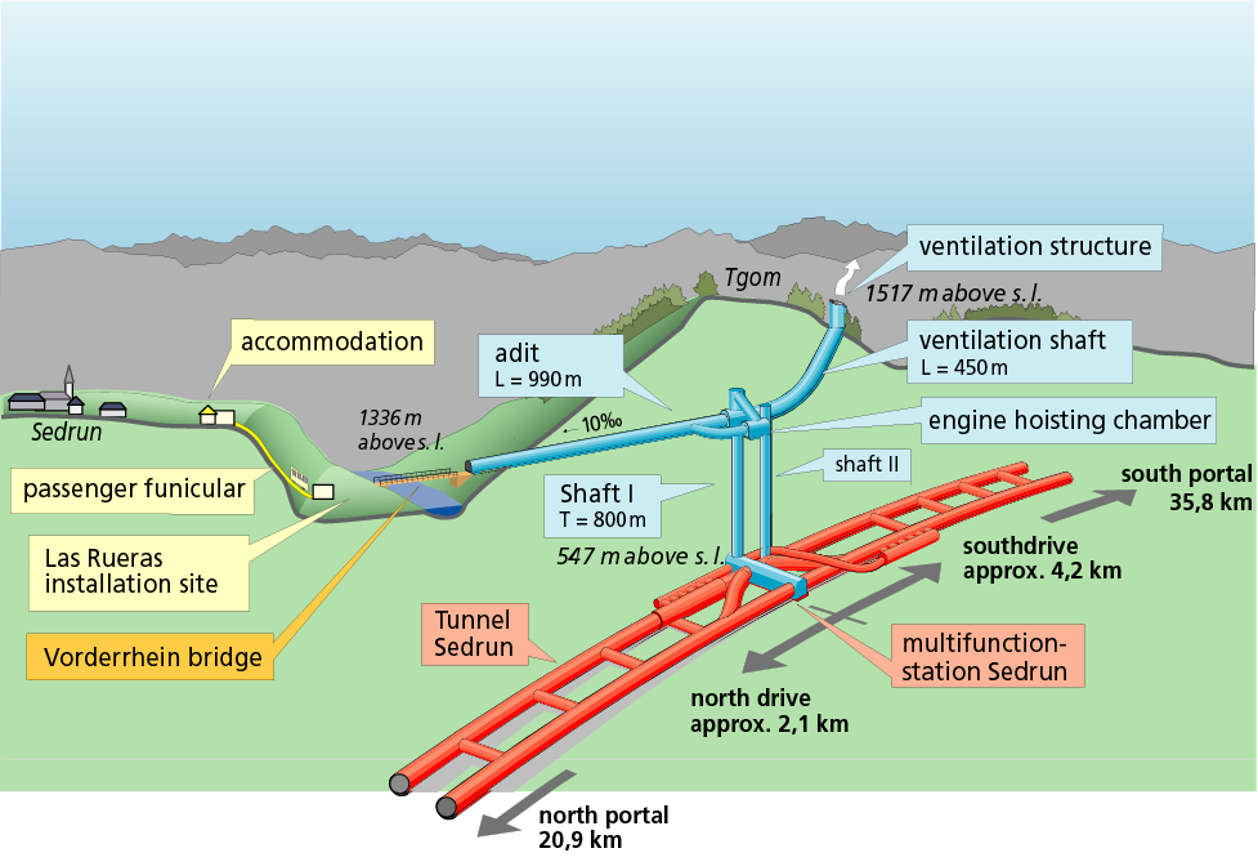

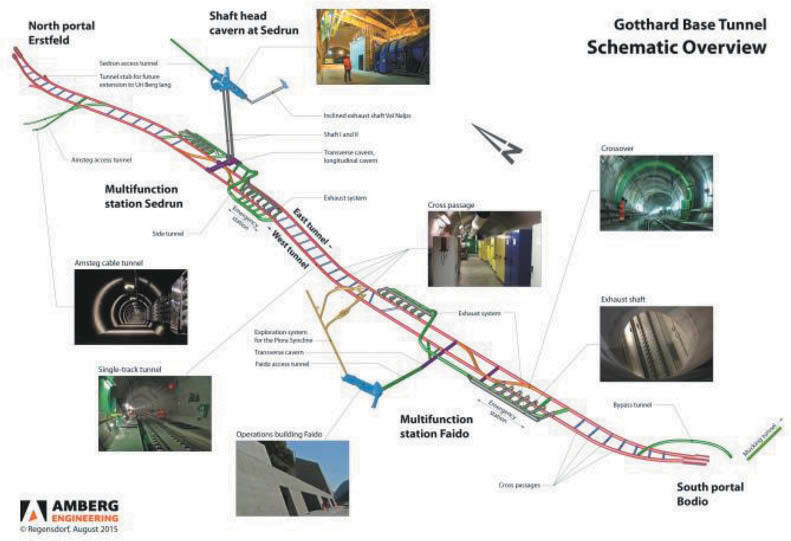

- Shuan Xiao talked about challenging inspection of 800m deep Sedrun shaft at the Gotthard Base Tunnel

If you have missed those presentations, you can still read both presented papers!

Our Papers from WTC2024

Uninterrupted continuous forecasting in mechanized tunnelling in rock

Abstract: The history of seismic exploration in tunnelling began in the early 1990s and continues until today. Especially in mechanised tunnelling, technologies are advancing. Digital construction requires a digital ground model that must be adapted during the construction to reassess newly gained knowledge about the ground risk. In fast tunnelling with average daily rates of 20-30 metres, geological surprises must no longer play a significant role. The innovative TSP 603-Impact system ensures seismic exploration wirelessly in the TBM area. With TSP-Impact, a mechanical source rapidly transmits high-energy seismic waves from the TBM's shield into the rock mass, enabling a prediction range of 100 metres or more. Wireless transceivers convert the signals into digital data and send them to a tablet. This procedure is carried out at the end of each stroke of the TBM. Thus, reflection-seismic data from different spatial positions on a possible fault can be collected and analysed. Flexible and subsequent installation of the system in the TBM makes it independent and yet easy to operate. Once the data from 20 strokes has been collected, it can be uploaded to the cloud with a unique encrypted identifier for data protection. If no trained site personnel are available to process the data, the data can very quickly reach an authorised expert who will process it and return with a geological forecast after 2 to 3 hours. The 3-D velocity distributions of P- and S-waves can be surface rendered to focus particularly on anomalies characterised by low-velocity zones. A geological model of the predicted area completes the picture. This allows the size and extent of the anomaly to be determined, preventing the risk of failure and collapse in the tunnel with an accuracy of 85-90%. With such a TSP operation once a week, continuous geological prediction can ensure smooth tunnelling.

Innovative shaft inspection system for the Gotthard Base Tunnel

Abstract: Amberg was commissioned by the Swiss Federal Railways SBB to develop a measurement system and execute an inspection of the 800 m deep Sedrun shaft B at the Gotthard Base Tunnel. A special shaft module equipped with multiple sensors was built to acquire a reliable data base. The inspection and condition assessment were performed based on this data using an inhouse inspection and data management platform. This paper presents the innovative measurement system developed and highlights the challenges encountered during this project.