In 2013, the Swedish government decided to extend the 'Tunnelbana', which dates back to 1950. It has 7 routes with 100 stations, 47 under and 53 above ground. As a sub-consultant of WSP Sweden, Amberg Engineering assists with its tunneling expertise on the new Yello Line. It will be 4 kilometers long with three new metro stations including city development.

Our part in the Tunnelbana

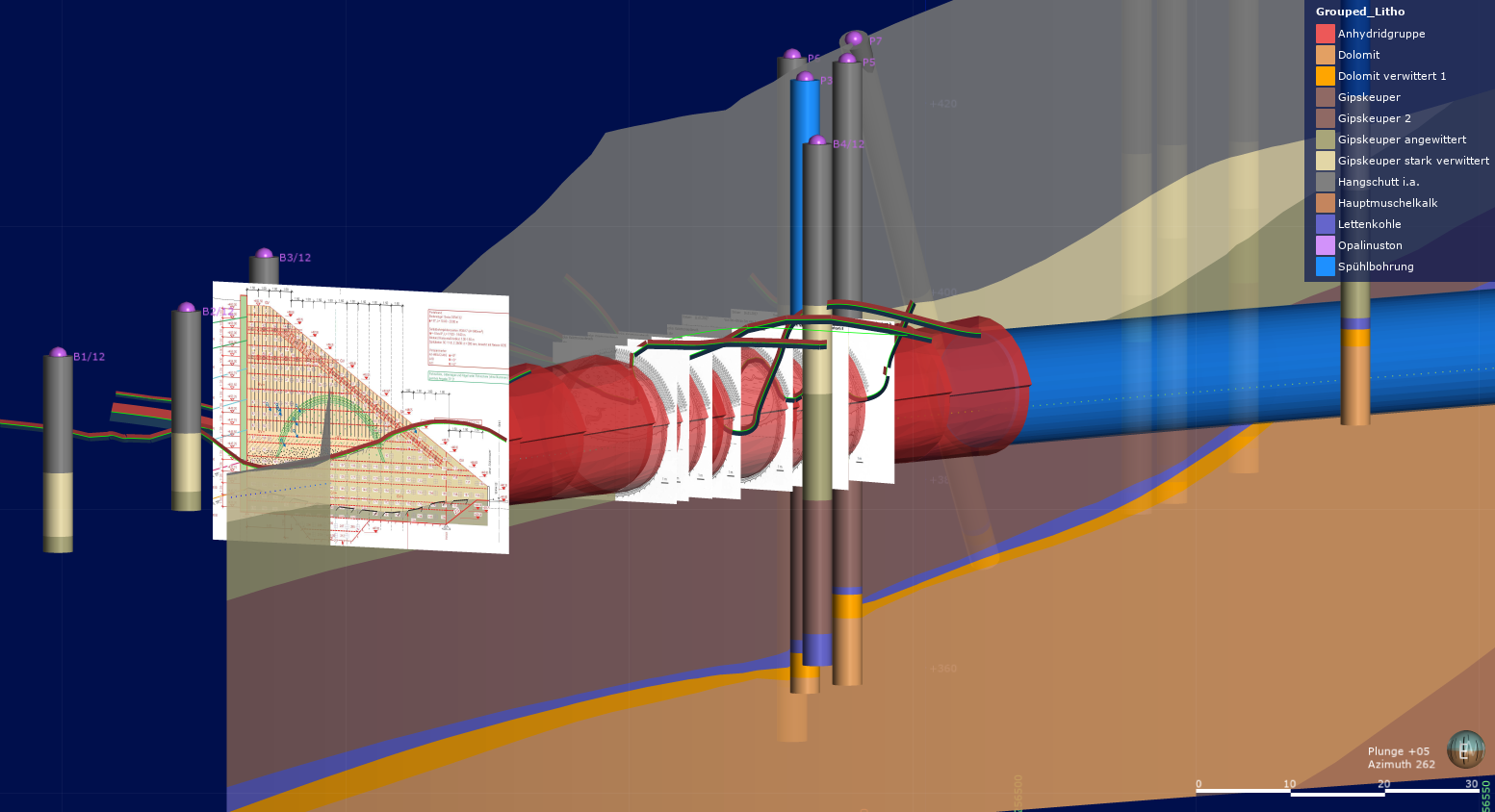

Our part of the project includes rock engineering consulting and solutions for challenging areas in the tunnels such as crossings and connections to the existing structure. We design the BIM-models of the tunnels, coordinate them, and do a 3D numerical simulation of station Hagastaden.

Complex on many levels – introducing new BIM processes

The Tunnelbana Yellow Line is a very complex project in different ways. First, there are the engineering challenges like complex geometrical situations and geological boundary conditions. Second, the project members and different stakeholders hold different opinions about how to approach the project. And third, new BIM processes have to be introduced and improved constantly. BIM is relatively new in tunneling projects and therefore many processes are not yet defined completely.

New software solutions and modelling processes

In such projects, the buildings – the metro, service, escape, and access tunnels – stretch over several kilometers and are based on a horizontal and vertical alignment. These two factors are problematic for many conventional 3D modelling solutions. The existing BIM software solutions are designed for building constructions. Thus, the Amberg engineering team had to find alternative software solutions and modelling processes.

Flexible and fast

The Tunnelbana project demanded very high flexibility of all the engineering disciplines as the project was modified during the design phase. The Swedish authorities decided that a third metro station, which was originally planned for later, should already be included at this stage.

As a consequence, the tunnel alignment had to be adjusted. That meant remodeling and redesigning a big part of the tunnels within a relatively short period of time. Of course, everything related to the tunnel alignment had to be included in the redesign – installations as well as road and track models. Thanks to BIM, the redesigning took much less time as all the sub-models were integrated in one coordination model.

Clear and direct communication

In regular coordination meetings – online and in person –, we exchanged news and forwarded updates and project changes directly to the responsible person. Thus, issues were resolved immediately. Being open-minded and adopting an interdisciplinary way of working in the whole planning team allowed us to work parallelly on the same coordination model.

'Conventional' collaboration methods like collecting e-mails, presentations, to do lists, documents and meeting results and transferring them into an issue list belong to the past. Simultaneous updates and direct links to the model are the new option. Consequently, our e-mail correspondence dropped by 60%.

Interdisciplinary working methods are key

Now we know that BIM requires highly interdisciplinary working methods. All involved disciplines were working alternatingly on the same parts of the model. We found that the various parts influenced each other to a great extent requiring quick exchange of information, excellent coordination and total flexibility. BIM furthermore enabled the rock team to quickly react to changing requirements and regulations, detect possible clashes with other disciplines and find their origins rapidly.

Magdalena Stelzer, one of the leading tunnel engineers of Amberg says: “We have learnt, that conventional coordination and review processes are no longer working with this new level of speed. BIM allows the different engineers to work simultaneously at the same project, that means communication has to be quicker and clearer. The number of issues to be treated showed this clearly, it decreased by close to 30%.”

Clearly defined roles

The excellent overall BIM coordination by WSP helped us to advance rapidly. As their sub-consultant we were in close contact with WSP and thus could constantly improve output and efficiency. BIM roles were clearly defined and communicated, workflows and communication processes were straight forward.

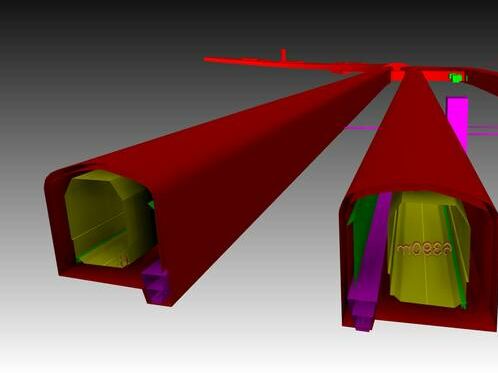

Parametric 3D tunnel model

Technically it was a parametric 3D tunnel model which made the design process faster and more flexible. The normal sections of the tunnels were linked to the tunnel alignment and the corresponding chainage. Changes in the tunnel alignment or the normal sections automatically adjusted the 3D models.

The BIM coordination and the parametric modelling allowed the team to react quickly to changing external regulations and requirements. “BIM coordination and collaboration tools increased efficiency and quality significantly,” explains Stelzer.

Effective issue tracking created relaxed atmosphere

On the whole, the new processes and possibilities coming with BIM created a much more relaxed atmosphere in the planning team. “The new tools detected errors or clashes very quickly and automatically sent a message to the responsible person. This made us feel confident about the high quality of our work,” so Stelzer.